| In retrospect, it is hard for me to imagine how anyone

could have considered the dirigible as being practical (to say nothing

of survivable) in a naval combat environment. In the 1920’s, however, the

task of finding an enemy fleet in the vast reaches of the ocean was so

difficult that an attempt to improve on the German efforts with lighter-than-air

dirigibles seemed worth the effort . With the very limited range and endurance

of aircraft at the time and with no hope that congress would fund an adequate

number of scout cruisers, Adm. Wm Moffett, chief of the USN Bureau of Aeronautics,

became convinced that larger and more powerful airships capable of carrying

“parasite” aircraft to extend the scouting radius and to allow the dirigible

itself to remain out of contact with the enemy might be the solution to

the scouting problem.

The huge ships proved to be extremely vulnerable to adverse weather

conditions (all but one of the USN rigid airships were destroyed by weather)

and proved less successful than hoped as scouts in fleet exercises. After

Adm. Moffett was killed in the crash of Akron and Macon was lost after

less than two years of service, the program was terminated. As beautiful

and imposing as they were, dirigibles proved a developmental dead end,

at least with the materials and design skill available in the 1920’s.

|

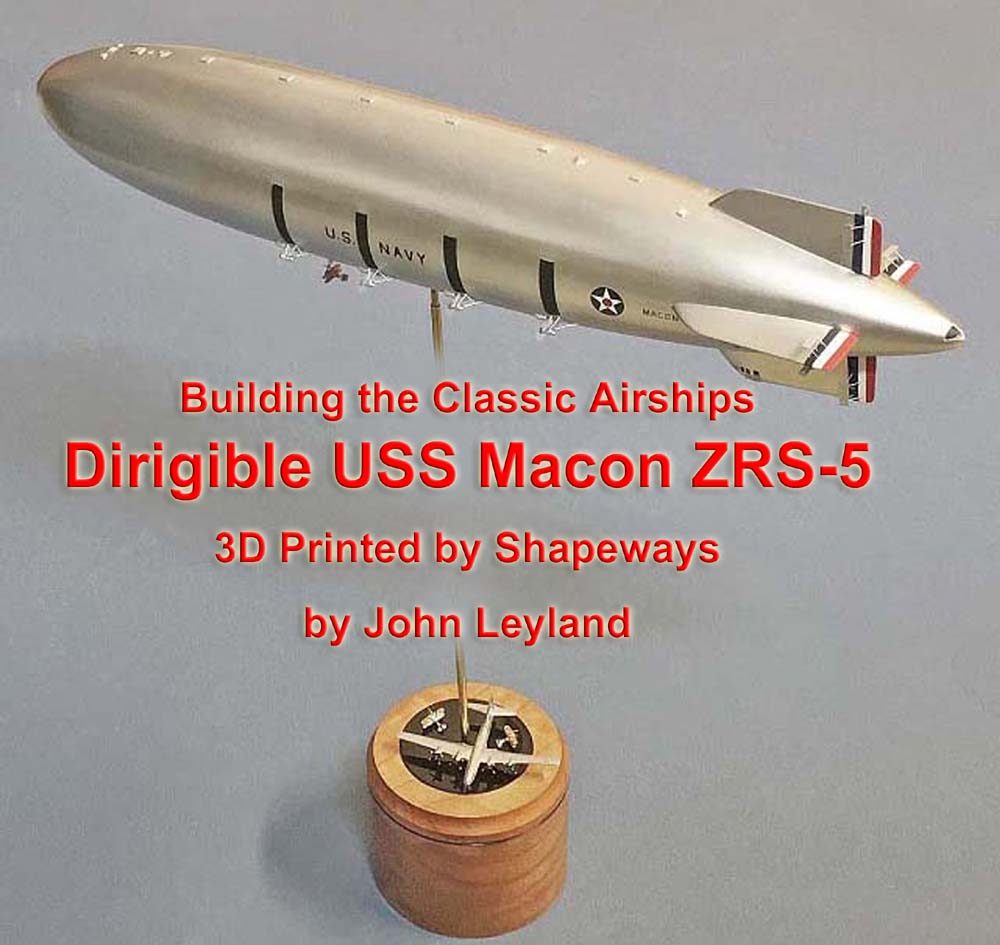

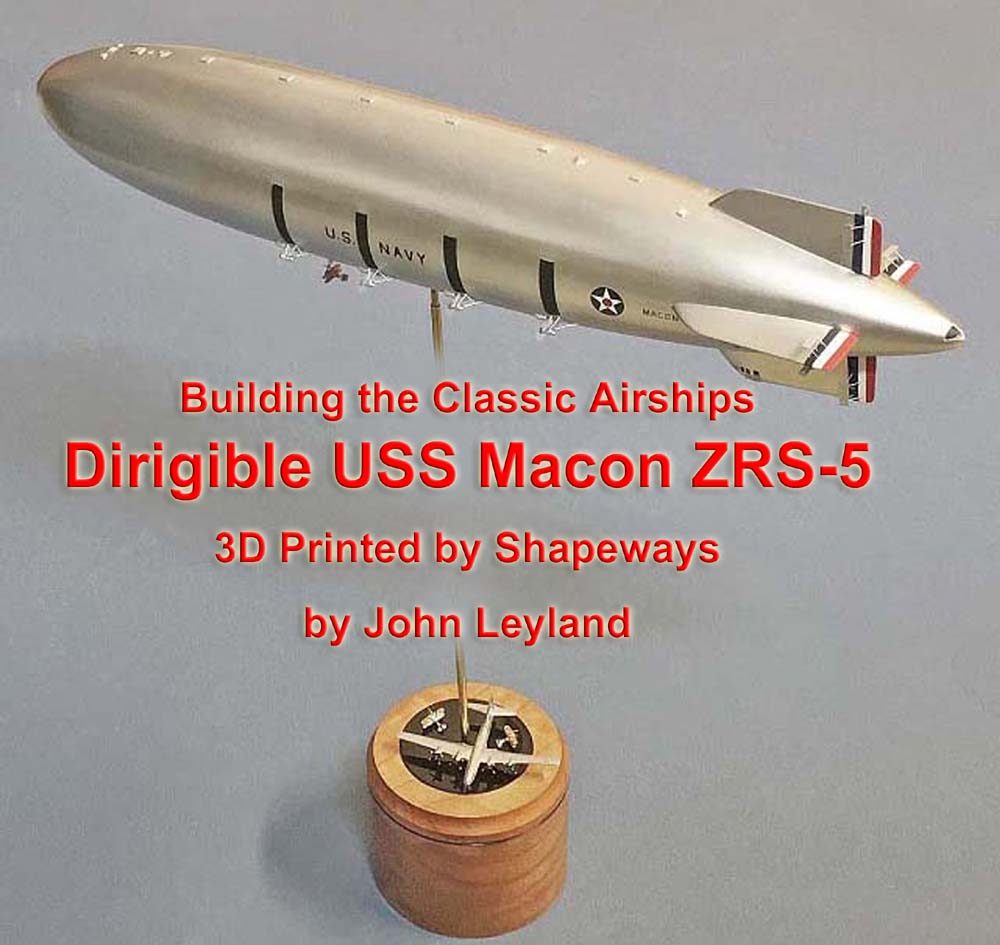

| For years I have hoped for a 1/700 dirigible kit to join my series

of aircraft carriers in representing the history of USN naval aviation.

Finally Derek Harrington of Classic Airships offered models of the Akron

and Macon 3D printed by Shapeways. The models have significant detail differences

reflecting the different ships and I found them to be very accurate. |

|

| The material used is called “Soft and Flexible” and lives up to its

name, being very porous and indeed flexible. The hull comes in three pieces

with the center section containing a very rudimentary representation of

the aircraft hangar. The gondola and engine mount set and the aircraft

set come as separate purchases.The limitations of 3D printing (at least

as used here) made these parts a questionable value. The gondola is very

well done. The engine mounts are far overscale, but by trimming off all

of the supports I found that the basic shafts are designed to easily and

perfectly align with the hull, solving the problem of aligning the eight

drive shafts with the hull and making them worth the money to me. The aircraft

fuselages are little gems, but all of the flying surfaces are too thick

and have to be replaced with plastic sheet (my experience with other aircraft

from Shapeways mastered by “Snafu” suggest that this is a matter of design

rather than a limitation of 3D printing itself). Again, the fuselages were

so much better than I could scratchbuild that they were worth the money

to me. The hull has all appropriate openings and makes an attempt at details

such as the dorsal gas vents and the large panels for an exhaust condensation

system on the sides, but the soft and flexible material is just too coarse

to represent fine detail. I cut off the gas vents and replaced them but

chose to live with the condensers. I’m glad I did the project, but I would

advise only experienced builders who REALLY want a dirigible to attempt

it. |

|

|

|

| I started the project by removing the hangar portion and spent a lot

of effort scratchbuilding a replacement (see photos). I then glued the

hull sections together with 5 minute epoxy and began giving the whole hull

several (probably six) heavy coats of Mr Surfacer 1000 by brush, sanding

between to keep from filling the “valleys” in the fabric. When I felt the

surface was smooth enough to accept a bare metal finish (think of trying

to apply a bare metal finish to a sock!), |

|

|

I used AK interactive Matt Aluminum on the hull and White Aluminum

for the lighter stripe along the line of the engines. The multiple engine

braces and the rudder and elevator balance structures were made from sprue.

I am satisfied with the model, but it wouldn’t stand up to IPMS level scrutiny. |

| Length 785 ft. (battleship Arizona was 608 ft.) Note size comparison

to 1/700 B-29 on the base. Beam 133ft. 7,401 260 cu. ft helium

8x 560hp Maybach 12 cyl . 55kt cruise speed 75 kt maxspeed

crew 60 5x Curtis F9C Sparrowhawk fighters Comm. 23 June, 1933

Lost 12 Feb, 1935 |

|

|

|

|

|